- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

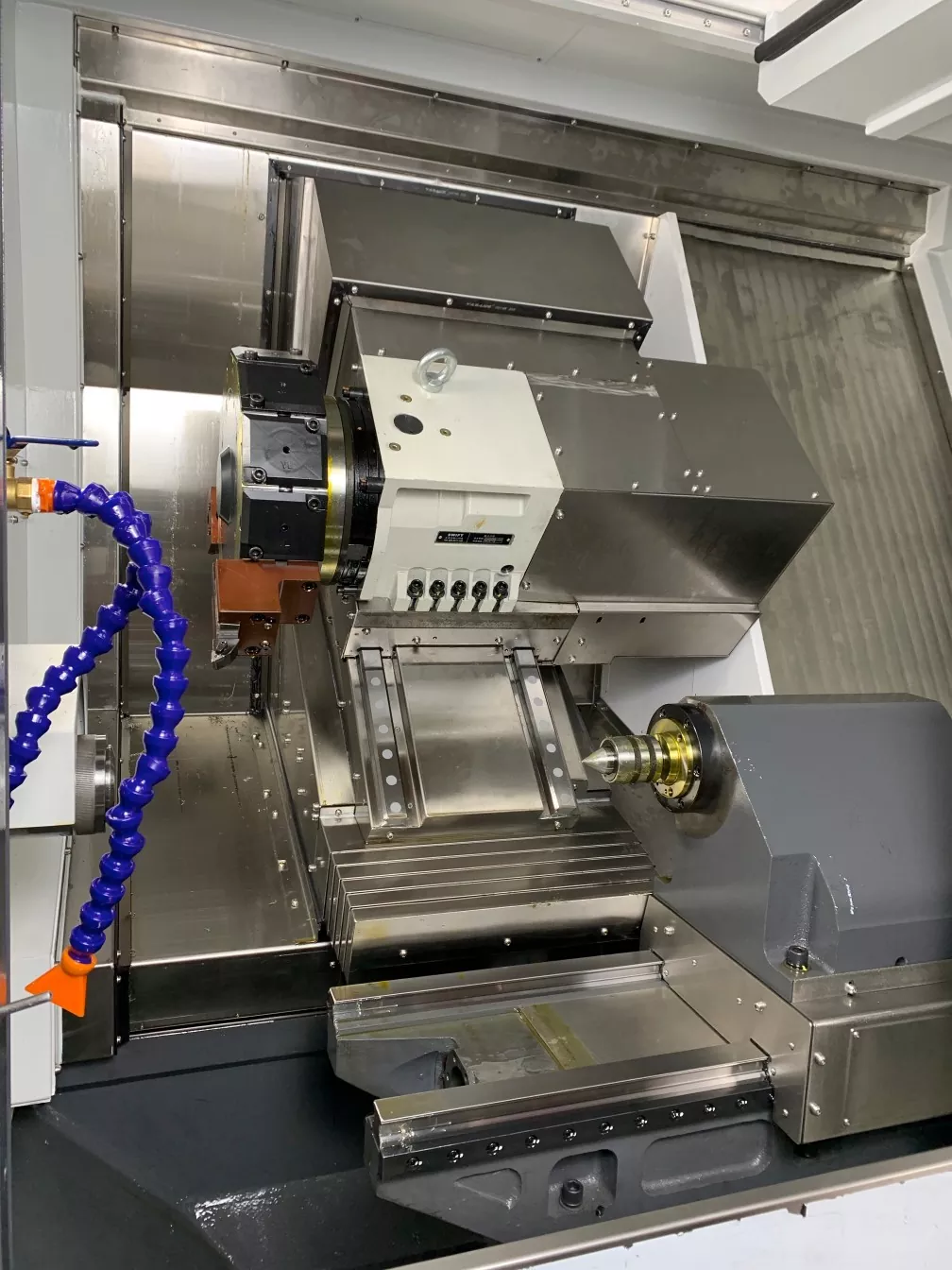

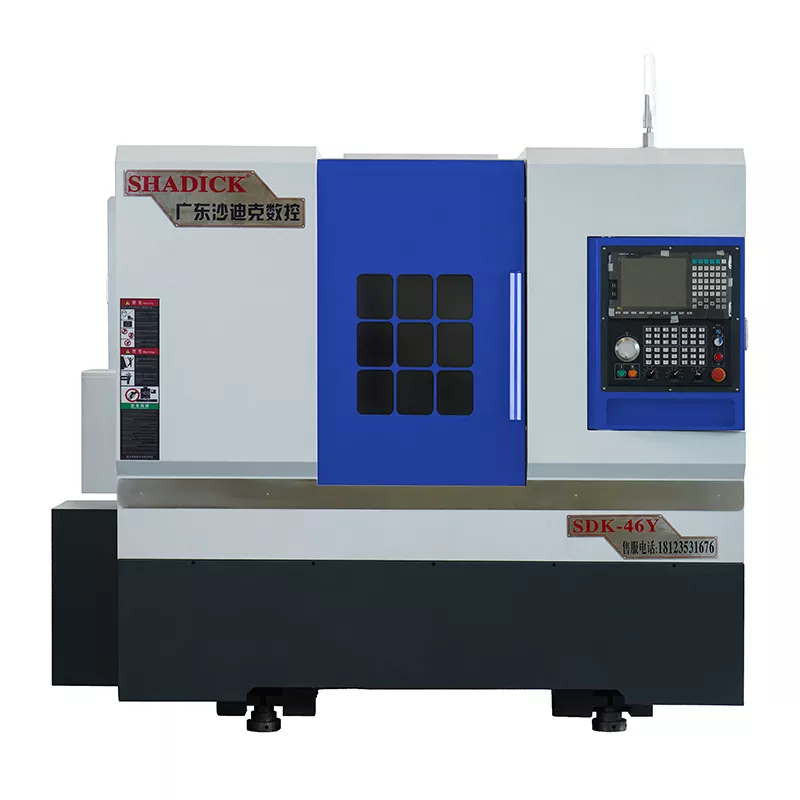

Interpolated Y-Axis Turn-Mill Compound CNC Machine Tools

The Interpolated Y-Axis Turn-Mill Compound CNC Machine Tools, as an advanced model within the series of lathe-mill complex machines, leverages its unique processing method, which combines the flexible fore-and-aft movement of the X-axis with the precise vertical displacement of the Y-axis, to achieve efficient integration of multi-process machining. This innovative design not only significantly enhances production efficiency but also seamlessly aligns with the urgent demands of modern manufacturing for efficient and high-quality production.

Send Inquiry

Our Interpolated Y-Axis Turn-Mill Compound CNC Machine Tools are equipped with imported high-precision linear guides, roller screws, and precision bearings.

It fully exploits the greatest advantages of four - axis linkage heavy cutting and high rigidity.

This is a turn-mill compound machining machine with an interpolated Y-axis power turret and tailstock center, a new model that replaces the straight Y-axis machine.

The programmable hydraulic tailstock center allows for one-key operation to extend or retract, facilitating easy workpiece clamping. It has two-speed control (fast and slow).

The power turret is used for machining high-rigidity parts, and the interpolated Y-axis power head can be used in combination with the turn-mill compound function to machine complex parts.

The bed of the machine tool adopts a high-low rail design with an angle ratio of 15:30 degrees, which can effectively ensure that the machine tool will not deform during long-term operation, and it features good rigidity and strong stability.

Product Parameter (Specification)

|

Processing capacity |

52CY |

|

Spin the bed body |

Φ600 |

|

The largest diameter processing |

φ350 |

|

Spindle |

|

|

Spindle nose |

A2-6 |

|

Bar aperture |

φ52 |

|

Spindle speed |

0-4500 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.005 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Tail seat travel |

|

|

Specification of tailstock sleeve |

Mo's 4# |

|

Tail seat travel |

500MM |

|

Tail seat movement method |

slider |

|

Top distance of chuck |

630MM |

|

Tail seat pressure range |

5-20 kilograms |

|

Top itinerary |

120MM |

|

Tail seat structure |

Precision sleeve type |

|

Axial Stroke |

|

|

X-axis travel radius |

260mm |

|

Z-axis Stroke |

620mm |

|

Y-axis Stroke |

﹢60mm﹣68mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

11KW |

|

X axis(servo)and motor |

3.1KW |

|

Z axis(servo)and motor |

3.1KW |

|

Y axis(servo)and motor |

2.4KW |

|

Power head motor |

5.5KW |

|

Turret |

|

|

Turret |

BMT55 |

|

Other |

|

|

Weight |

5000KG |

|

Mechanical dimensions |

2900*1950*2100 |

Product Festure And Application

Interpolated Y-Axis Turn-Mill Compound CNC Machine Tools are widely used in various manufacturing industries, especially in the processing of high-precision and complex parts such as docking inserts, automotive parts, medical equipment, etc., which have significant advantages. In addition, it can also be used to process parts with complex geometric shapes, various sizes, and high precision requirements, such as cylindrical surfaces, conical surfaces, stepped surfaces, spherical surfaces, and other types of rotating surfaces.

Production Details

It is driven and controlled by a screw rod and a servo motor. The program instructions for movement and thrust can be set, and the operation is simple.

It adopts the design of a programmable hydraulic tailstock, which makes it easier to ensure the roundness and concentricity when processing ultra-long and slender shaft parts.

The programmable hydraulic tailstock can control the forward, backward movement and stopping of the tailstock through M-codes and K-codes. Moreover, it allows for arbitrary adjustment of the pressure. It is simple, convenient, safe and reliable.