- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

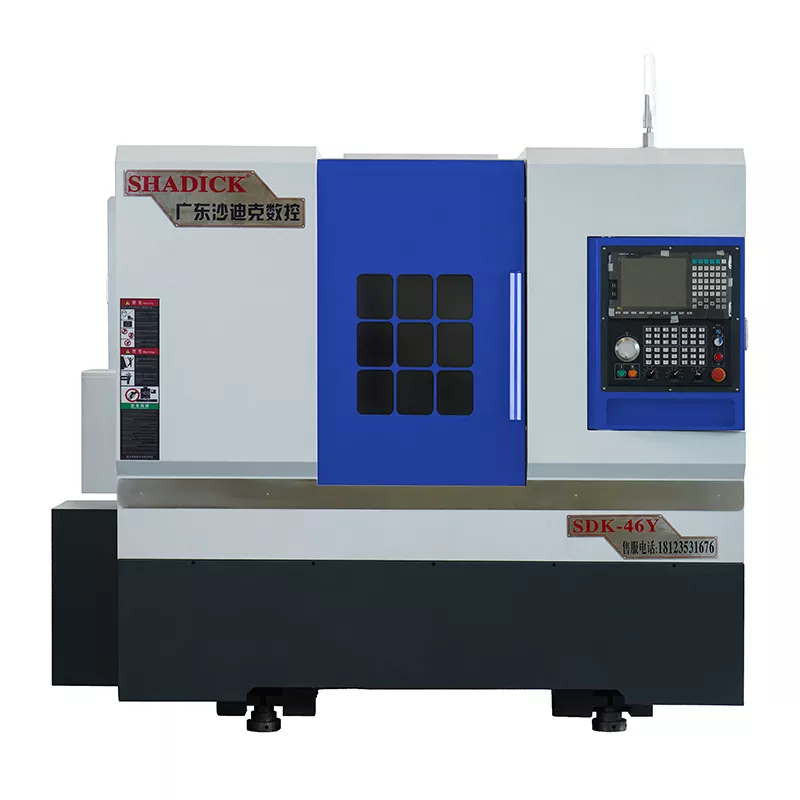

52-Tailstock Turn-Mill Composite CNC Machine

Shadick 52-Tailstock Turn-Mill Composite CNC Machine can be flexibly configured with ordinary or programmable hydraulic tailstock according to customer needs. Ordinary hydraulic tailstock is easy to operate, but its flexibility and accuracy are limited; The programmable hydraulic tailstock, on the other hand, relies on advanced programming control to achieve high precision and flexible machining, meeting complex requirements.

Send Inquiry

The power turret's Y-axis of the Shadick 52-Tailstock Turn-Mill Composite CNC Machine is controlled by 4 linear guides or double hardened guides, which significantly improves precision and high rigidity.

It is equipped with a programmable hydraulic tailstock. With just one press of a button, you can extend or retract the tailstock, making it easy to clamp workpieces. It has two-speed control (fast and slow).

It has the function of four - axis linkage machining for turning, milling, drilling, tapping, etc., and can complete drilling and tapping on the shaft ends of parts.

The power turret can be used to machine high-rigidity parts. The true Y-axis power head can be combined with the turn-mill compound function to machine complex parts.

It can perform large - scale precision machining on steel and stainless-steel parts, as well as drilling and tapping on the shaft ends. The machine with a tailstock can process long-shaft parts.

There is a power tool function module on the side that can perform functions such as drilling, tapping, and milling flats, enabling precise drilling and milling of various shaft parts.

The power head motor has a power of 5.5 KW and is equipped with a self-contained cooling system. Its maximum rotational speed can reach 8,000 revolutions per minute. It can perform 24-hour machining without overheating or triggering an alarm.

Product Parameter (Specification)

|

Processing capacity |

52Y |

|

Spin the bed body |

φ500 |

|

The largest diameter processing |

Φ350 |

|

Spindle |

|

|

Spindle nose |

A2-6 |

|

Bar aperture |

φ52 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.005 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Tail seat travel |

|

|

Specification of tailstock sleeve |

Mo's 5# |

|

Tail seat travel |

420MM |

|

Tail seat movement method |

slider |

|

Top distance of chuck |

450MM |

|

Tail seat pressure range |

5-20 kilograms |

|

Top itinerary |

120MM |

|

Tail seat structure |

Precision sleeve type |

|

Axial Stroke |

|

|

X-axis Stroke |

260mm |

|

Z-axis Stroke |

520mm |

|

Y-axis Stroke |

±45mm/±50mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

11KW |

|

X axis(servo)and motor |

3.1KW |

|

Z axis(servo)and motor |

3.1KW |

|

Y axis(servo)and motor |

2.4KW |

|

Power head motor |

5.5KW |

|

12- Station Power Turret (BMT45) |

King CNC from Taiwan, China |

|

Power Head 0 - degree |

2 |

|

Power Head 90 - degree |

2 |

|

Other |

|

|

Weight |

3700KG |

|

Mechanical dimensions |

2850*1780*2040 |

Product Feature And Application

The turn-mill compound machine tool inherently features high efficiency and multi-functionality. It is capable of completing a variety of machining tasks in a single clamping, making it highly suitable for the manufacturing industries that require efficient production. It is applicable to the long-axis machining in industries such as automotive parts, transmission industry, and wind power generation.

Production Details

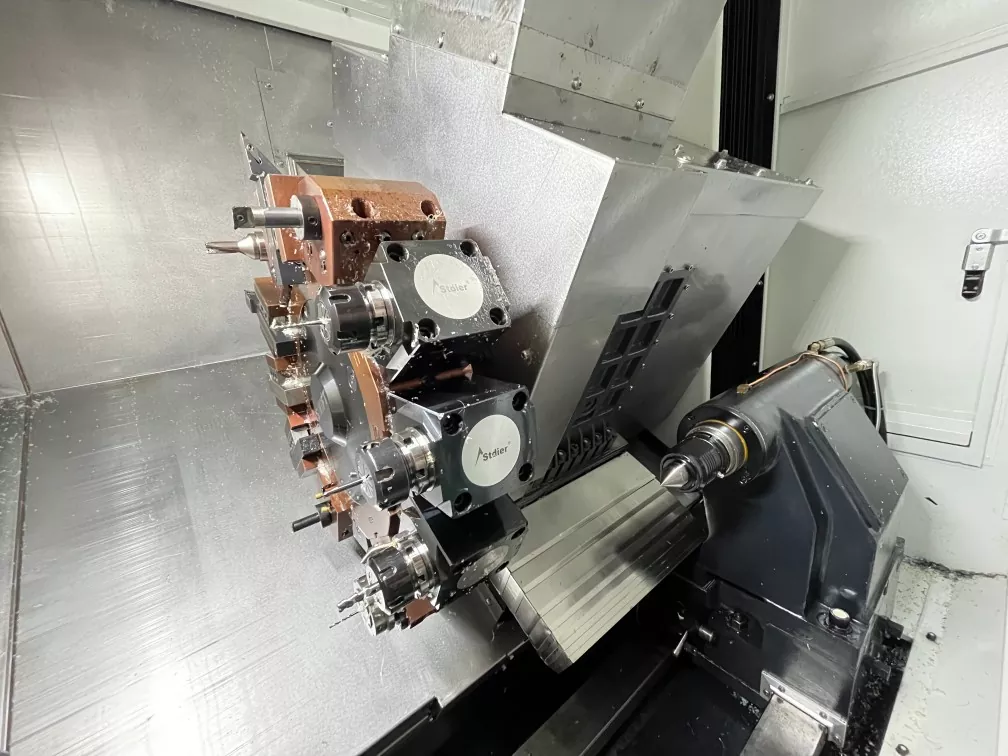

52-Tailstock Turn-Mill Composite CNC Machine Internal structure of machine tool,The BMT55 servo-driven turret improves the reliability of indexing and ensures the high rigidity during milling.