- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

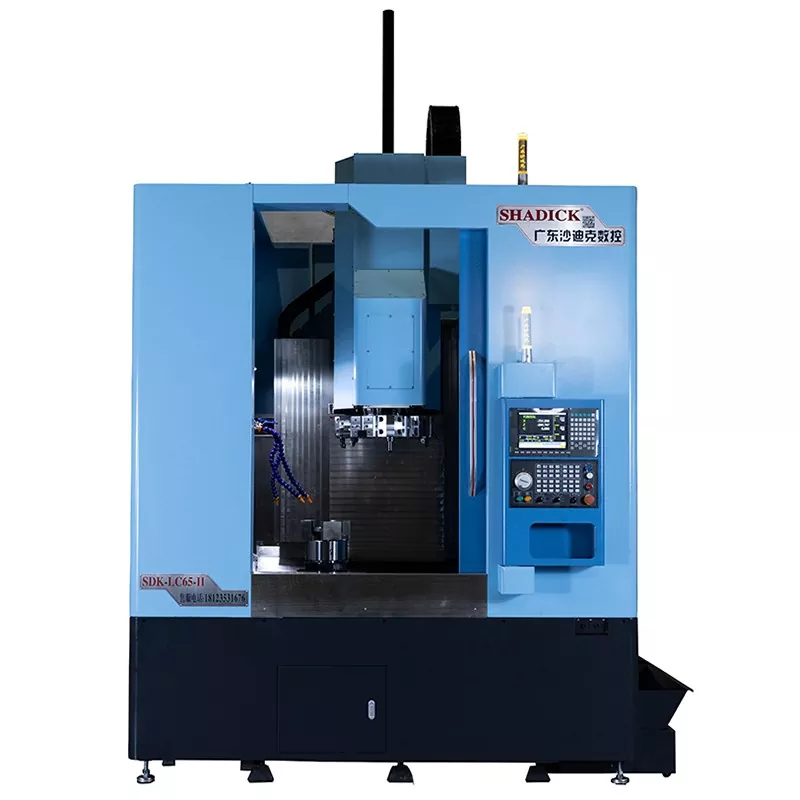

80 Vertical CNC Machine Tools

The 80 Vertical CNC Machine Tools is equipped with multi axis control, which flexibly adapts to the multi-faceted machining needs of complex workpieces. The workbench position is intuitive, the programming is simple, and it is convenient for operators to perform machining operations and program adjustments. It can handle a variety of materials, including metals, non metals, etc., to meet the processing needs of different industries.

Send Inquiry

Stable processing: The workpiece is naturally positioned by gravity, providing a stable cutting ring to ensure high-precision processing. Paired with the German Schott turret, 80 Vertical CNC Machine Tools has high precision, precise positioning, and strong rigidity.

Both axes (XZ) use heavy-duty roller tracks of 55mm and screw rods of 50mm, supported by six heavy-duty sliders

Suitable for processing parts with large outer diameters and heavy weights.

The machine tool base is nearly square, with high rigidity, reducing the influence of deformation and movement.

Product Parameter (Specification)

|

Processing capacity |

LC60 |

LC80 |

|

Spin the bed body |

φ700 |

φ850 |

|

The largest diameter processing |

φ600 |

φ800 |

|

Spindle |

||

|

Spindle nose |

A2-8 |

A2-11 |

|

Bar aperture |

φ86 |

φ60 |

|

Spindle speed |

0-2000 |

|

|

Mechanical precision |

||

|

Repeat positioning accuracy |

±0.008 |

|

|

Spindle firing |

≤0.008/100mm |

|

|

Spindle taper |

≤0.008/100mm |

|

|

X, Z crosshair |

≤0.008/100mm |

|

|

X/Z axis fast-moving speed |

24m/min |

|

|

Axial Stroke |

||

|

X-axis Stroke |

500mm |

|

|

Z-axis Stroke |

750mm |

|

|

Motor Power |

||

|

Spindle(servo)and motor |

15KW |

|

|

X axis(servo)and motor |

2.9KW |

|

|

Z axis(servo)and motor |

2.9KW |

|

|

Turret |

||

|

Turret |

8 workstations with 380 tool trays |

|

|

Other |

||

|

Weight |

9000KG |

11000KG |

|

Mechanical dimensions |

2450*2330*2650 |

|

Product Festure And Application

Heavy and large parts processing, such as shafts, gears, wheel hubs, etc., are widely used in industries such as heavy machinery manufacturing, mining, and oil extraction. Fields requiring high precision, such as aerospace components, require extremely high machining accuracy and surface quality. Manufacturing of large molds and equipment components: meeting the complex shapes and high-precision requirements of large components such as mold manufacturing and power generation equipment.

Production Details

Display of internal structure of 80 Vertical CNC Machine Tools

Machine tool control system optional: Taiwan synesc、Fanuc、Germany Siemens