- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

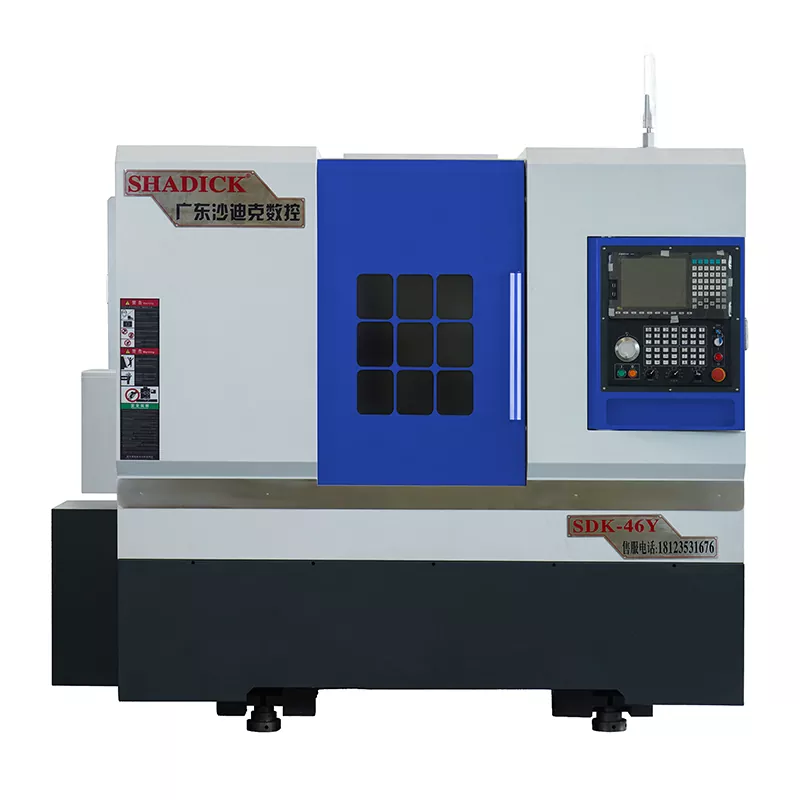

46-Turning and Milling Compound CNC Machine Tools

Shadick not only provides high-end 46-Turning and Milling Compound CNC Machine Tools, but also excels in customized services. Our technical team will carefully design the process flow, configure tools, and plan automation solutions based on the specific needs of each customer, truly providing a "one-stop" solution for all customers. Choosing Shadick means choosing a manufacturing partner that can achieve efficient and worry free operations.

Send Inquiry

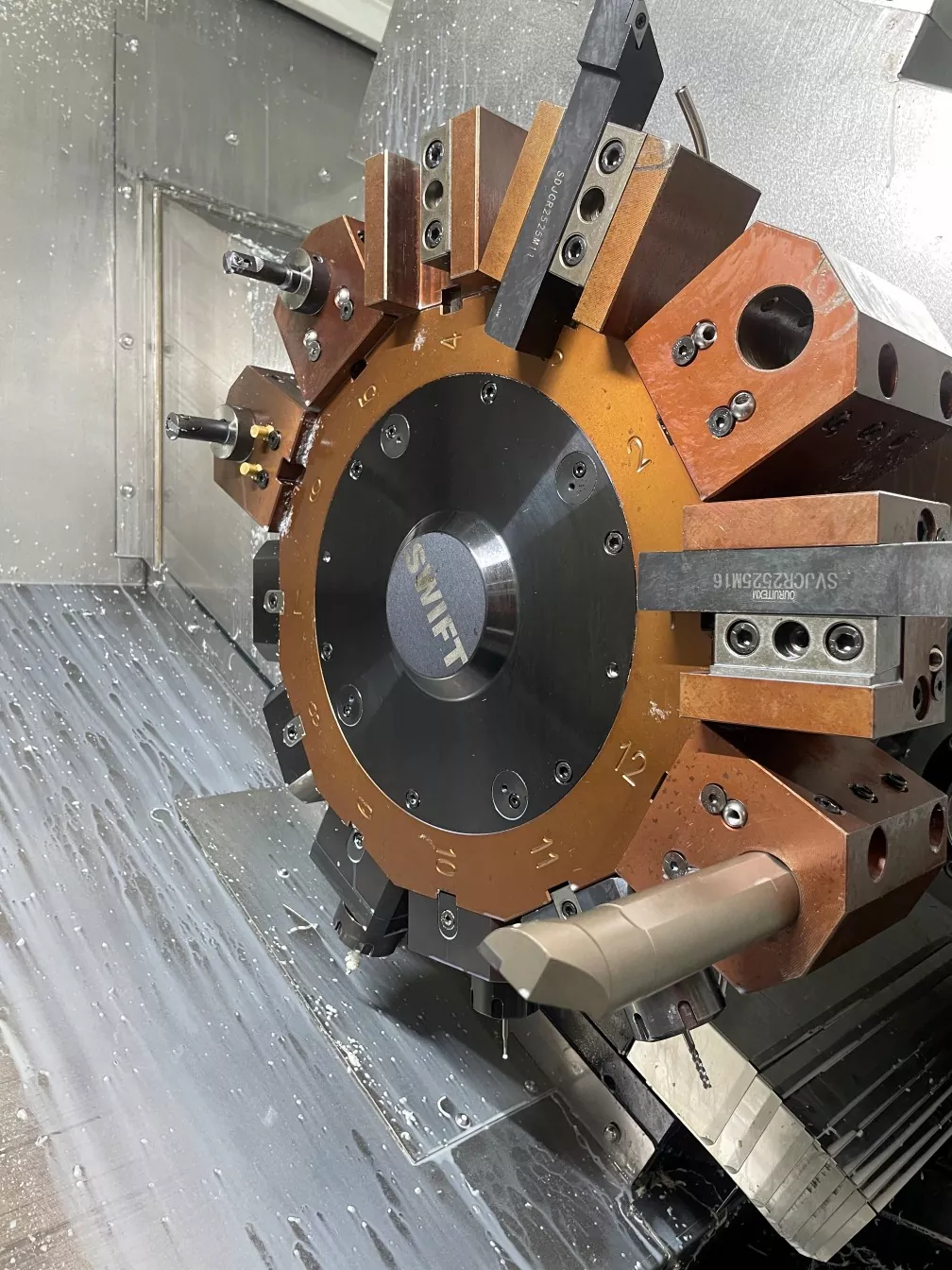

Our 46-Turning and Milling Compound CNC Machine Tools utilize true Y-axis power turret control to perform complex part machining.

Each axis is equipped with imported high-precision linear guides, roller screws, and precision bearings.

It can perform large-scale precision machining of steel parts and stainless steel, as well as drilling and tapping of shaft ends.

The Y-axis of the direct coupled power turret adopts 4-wire rail/double hard rail control, which greatly improves precision and high rigidity.

Product Parameter (Specification)

|

Processing capacity |

46Y |

|

Spin the bed body |

Φ450 |

|

The largest diameter processing |

Φ350 |

|

Spindle |

|

|

Spindle nose |

A2-5 |

|

Bar aperture |

φ46 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.003 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Axial Stroke |

|

|

X-axis radius |

250mm |

|

Z-axis Stroke |

400mm |

|

Y-axis Stroke |

±35mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

7.5KW |

|

X axis(servo)and motor |

3.1KW |

|

Z axis(servo)and motor |

3.1KW |

|

Y axis(servo)and motor |

2.4KW |

|

Power head motor |

5.5KW |

|

12 - Station Power Turret (BMT40) |

King CNC from Taiwan, China |

|

Power Head 0 - degree |

2 |

|

Power Head 90 - degree |

2 |

|

Other |

|

|

Weight |

3600KG |

|

Mechanical dimensions |

2730*1710*1920 |

Product Festure And Application

The Shadick 46-Turning and Milling Compound CNC Machine Tools combines the functions of a lathe and a machining center. It is specifically designed to handle products with high requirements for precision, concentricity, and coaxiality. Usually, it is used for processing spare parts in fields such as the automotive, aerospace, and mold manufacturing industries. With a single clamping, it can complete the processing of complex parts, shortening the production time and reducing costs.

Production Details

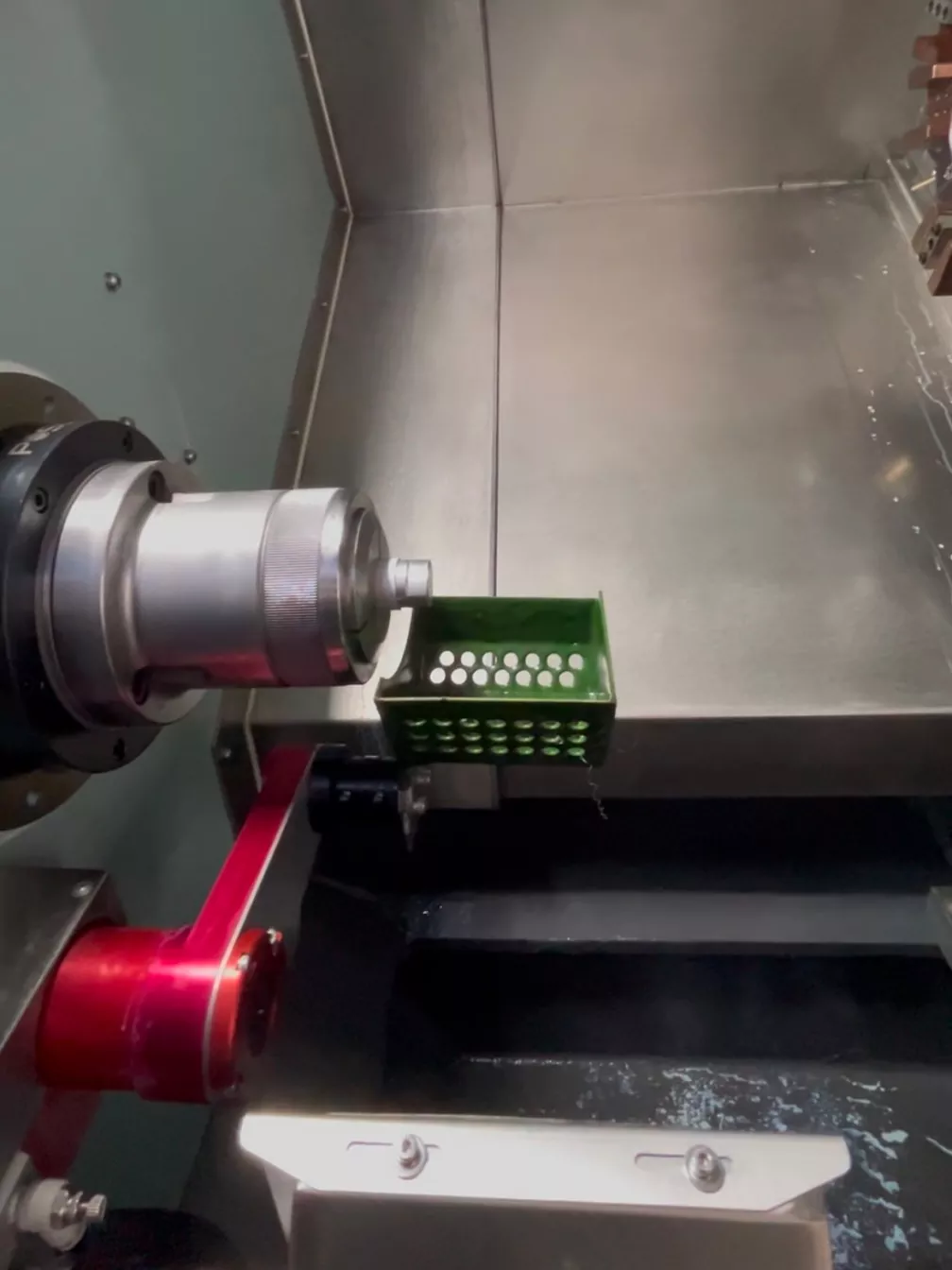

46-Turning and Milling Compound CNC Machine Tools Internal Structure Display

Our equipment allows for the optional installation of a workpiece collector and an automatic feeder according to customers' needs, which can save time and labor, and reduce costs.