- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

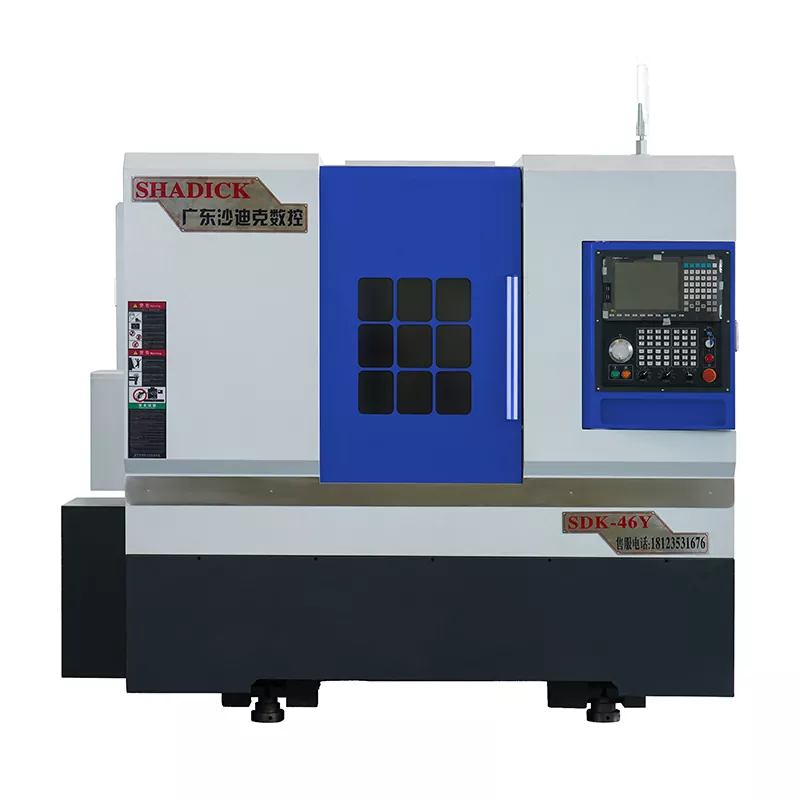

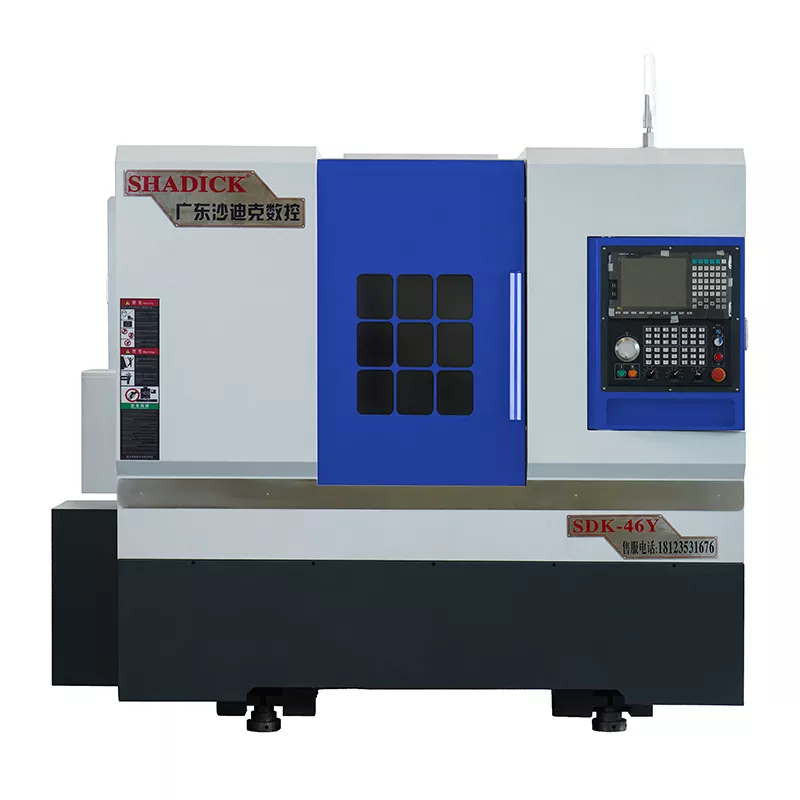

46-Tailstock Turn-Mill Composite CNC Machine

The 46-Tailstock Turn-Mill Composite CNC Machine is a commonly used piece of equipment in the manufacturing industry, combining the functions of turning, milling, drilling, tapping, and more, enabling the completion of multiple tasks with a single setup. Our turn-mill center is particularly suitable for processing complex parts, such as slender components and intricate curved surfaces, which are often difficult to achieve with high efficiency and precision using traditional machining methods.

Send Inquiry

46-Tailstock Turn-Mill Composite CNC Machine can simultaneously achieve multi-process turn-mill compound functions such as turning, milling, drilling, tapping, hobbing, and slotting.

The spindle's C-axis is equipped with a high-resolution magnetic ring encoder, enabling continuous indexing (with an indexing accuracy of up to 0.01 degrees). It is assembled coaxially with the machine tool to ensure the positioning accuracy and high reliability of the C-axis.

It adopts a fully enclosed protective design, which effectively protects important components such as screws, guides, and bearings. It is aesthetically pleasing, stable, and durable.

It uses the Taiwan Syntec operating system, which allows for rapid positioning during high - speed operation, effectively improving the indexing efficiency and accuracy.

Product Parameter (Specification)

|

Processing capacity |

46Y |

|

Spin the bed body |

Φ450 |

|

The largest diameter processing |

φ350 |

|

Spindle |

|

|

Spindle nose |

A2-5 |

|

Bar aperture |

φ46 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.005 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Tail seat travel |

|

|

Specification of tailstock sleeve |

Mo's 5# |

|

Tail seat travel |

370MM |

|

Tail seat movement method |

slider |

|

Top distance of chuck |

450MM |

|

Tail seat pressure range |

5-20 kilograms |

|

Top itinerary |

120MM |

|

Tail seat structure |

Precision sleeve type |

|

Axial Stroke |

|

|

X-axis Stroke |

250mm |

|

Z-axis Stroke |

510mm |

|

Y-axis Stroke |

±35mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

7.5KW |

|

X axis(servo)and motor |

3.1KW |

|

Z axis(servo)and motor |

3.1KW |

|

Y axis(servo)and motor |

2.4KW |

|

Power head motor |

5.5KW |

|

15- Station Power Turret (BMT40) |

King CNC from Taiwan, China |

|

Power Head 0 - degree |

2 |

|

Power Head 90 - degree |

2 |

|

Other |

|

|

Weight |

3600KG |

|

Mechanical dimensions |

2850*1780*2040 |

Product Festure And Application

The turn-mill complex with tailstock is a versatile machining equipment that combines the functions of turning and milling, and features a tailstock device to support the processing of various workpieces. This 46-Tailstock Turn-Mill Composite CNC Machine's high precision, high efficiency, and capability for processing complex-shaped workpieces make it widely used in multiple industries.

Production Details

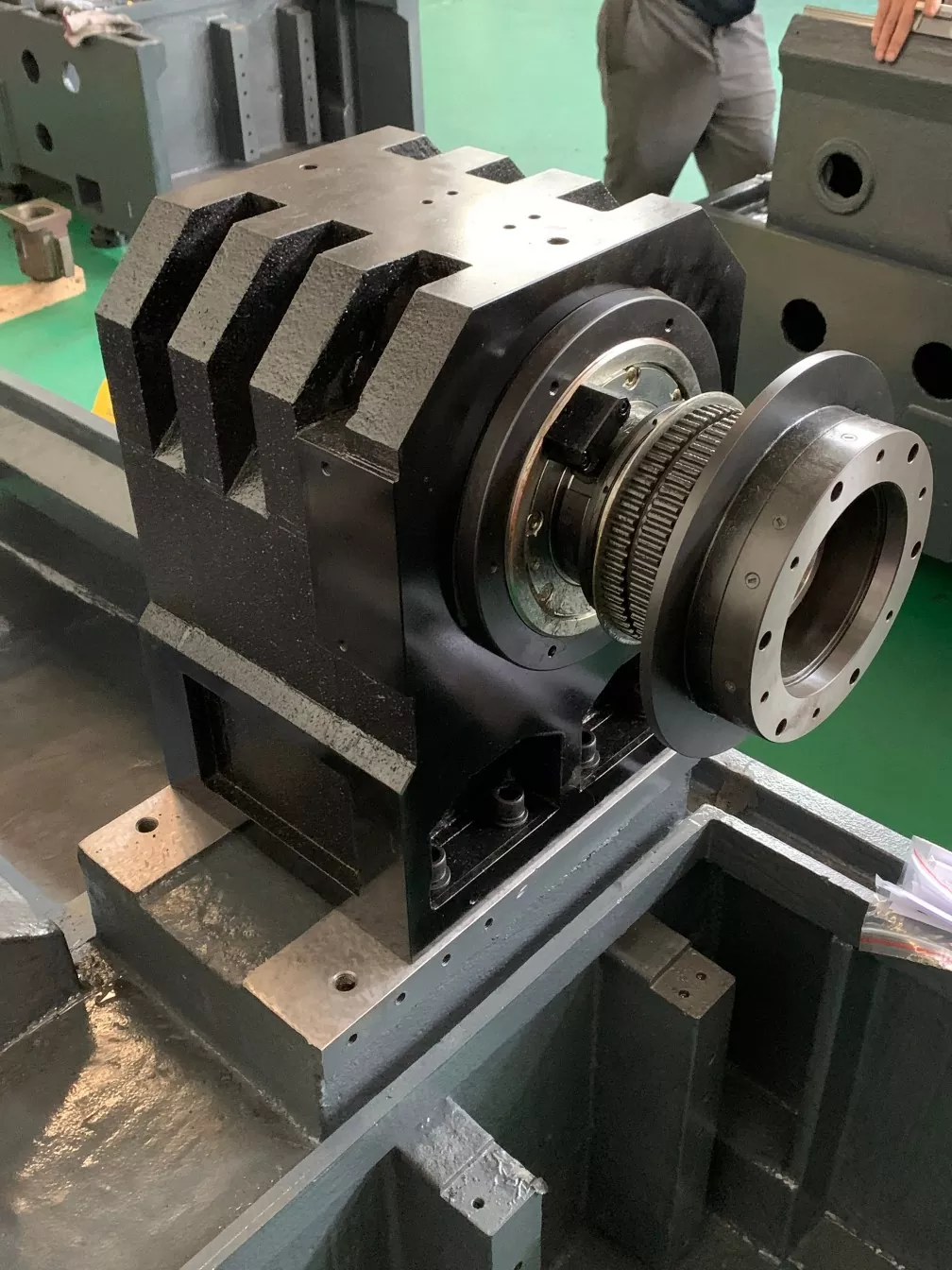

46-Tailstock Turn-Mill Composite CNC Machine Internal structure of machine tool.

The 15-station power turret can load more tools. When machining complex parts, there is no need to frequently change the tools, which reduces the downtime caused by tool changing and improves the machining efficiency.