- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

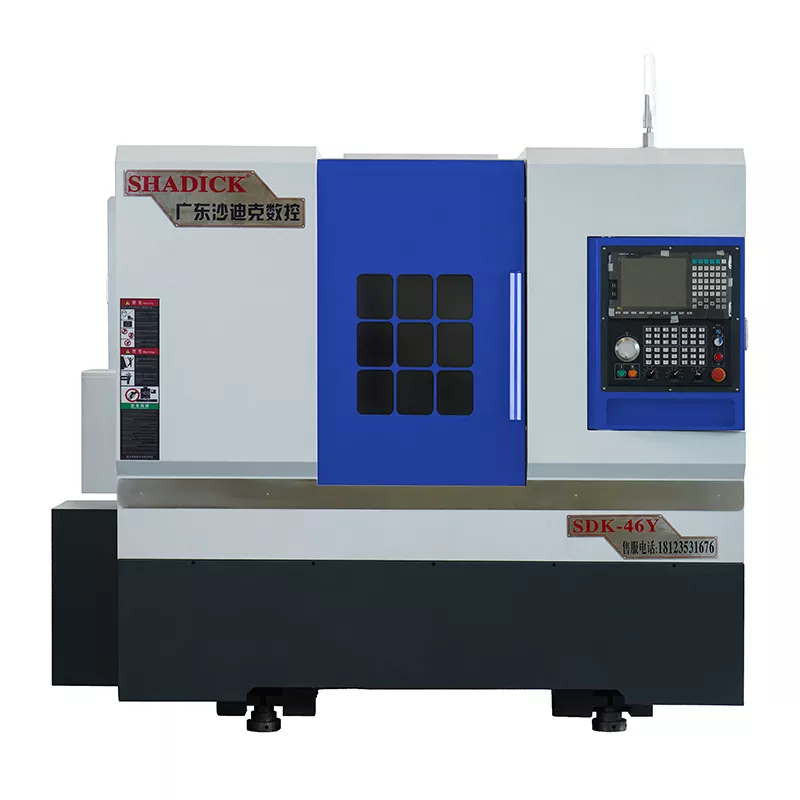

52-Turning and Milling Compound CNC Machine Tools

The Shadick factory boasts a comprehensive product line, encompassing small CNC lathes, gang tool CNC lathes, turret-type CNC lathes, turn-mill centers, and vertical CNC machines, capable of fully meeting the processing needs of various users for products of different scales, sizes, and materials. Especially noteworthy is our 52-Turning and Milling Compound CNC Machine Tools, which integrates the turning capabilities of a CNC lathe with some of the functions of a machining center, achieving a perfect blend of efficient processing and superior performance, earning it the title of the king of cost-effectiveness.

Send Inquiry

Compared to the 46-Turning and Milling Compound CNC Machine Tools, the 52-Turning and Milling Compound CNC Machine Tools feature a more powerful spindle motor and a larger spindle bore. The higher motor power is suitable for heavier cutting tasks, enabling faster material removal and improved processing efficiency. The 52-mm spindle bore can accommodate larger diameter bars or tools, making it suitable for processing larger workpieces. It is capable of handling more complex workpiece shapes and larger workpiece sizes, catering to a wider range of processing needs.

Product Parameter (Specification)

|

Processing capacity |

52Y |

|

Spin the bed body |

φ500 |

|

The largest diameter processing |

Φ350 |

|

Spindle |

|

|

Spindle nose |

A2-6 |

|

Bar aperture |

φ52 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.005 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Axial Stroke |

|

|

X-axis radius |

260mm |

|

Z-axis Stroke |

450mm |

|

Y-axis Stroke |

±45mm/±50mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

11KW |

|

X axis(servo)and motor |

3.1KW |

|

Z axis(servo)and motor |

3.1KW |

|

Y axis(servo)and motor |

2.4KW |

|

Power head motor |

5.5KW |

|

15- Station Power Turret (BMT45) |

King CNC from Taiwan, China |

|

Power Head 0 - degree |

2 |

|

Power Head 90 - degree |

2 |

|

Other |

|

|

Weight |

3600KG |

|

Mechanical dimensions |

2850*1780*2040 |

Product Festure And Application

The lathe-milling complex machine inherently boasts high efficiency and versatility, capable of completing a variety of processing tasks in a single setup, making it suitable for manufacturing industries that require efficient production. The 52 lathe-milling complex machine, in particular, excels further in terms of processing accuracy and rigidity, making it an ideal choice for industries with stringent requirements on component precision and strength, such as aerospace and automotive manufacturing.

Production Details

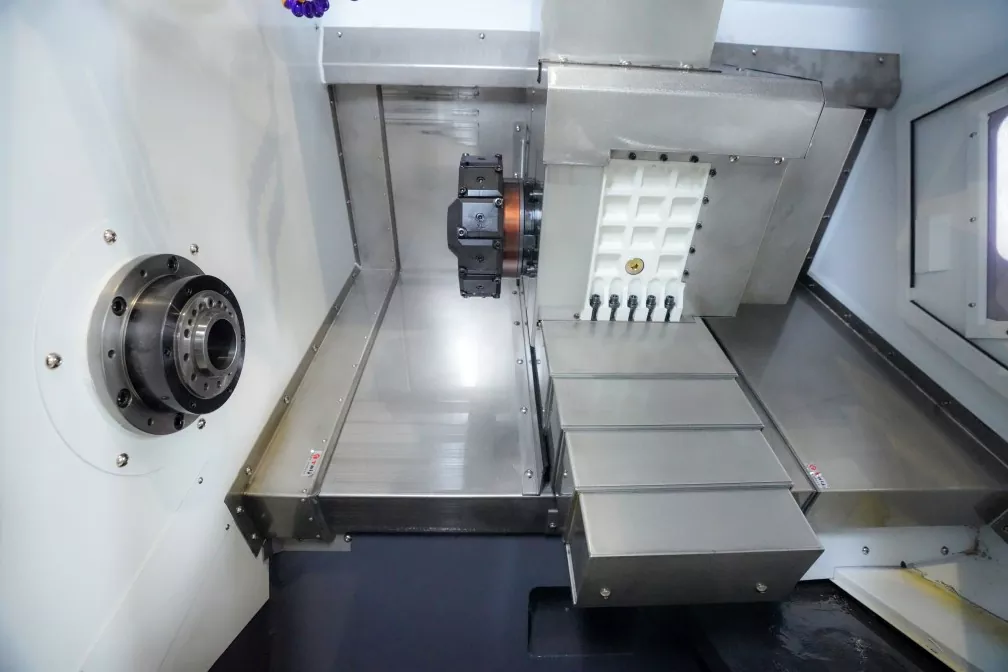

52-Turning and Milling Compound CNC Machine Tools Internal structure display