- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

36-Row Tool CNC Machine Tools

36-Row Tool CNC Machine Tools, as our company's best-selling small precision CNC machine tool, is easy to operate and has strong stability. Faced with the growing demand for personalized customization in the market, 36 Roll Tool CNC Machine Tools, with its fast tool changing ability and flexible programming features, can efficiently complete small batch and multi variety production tasks.

Send Inquiry

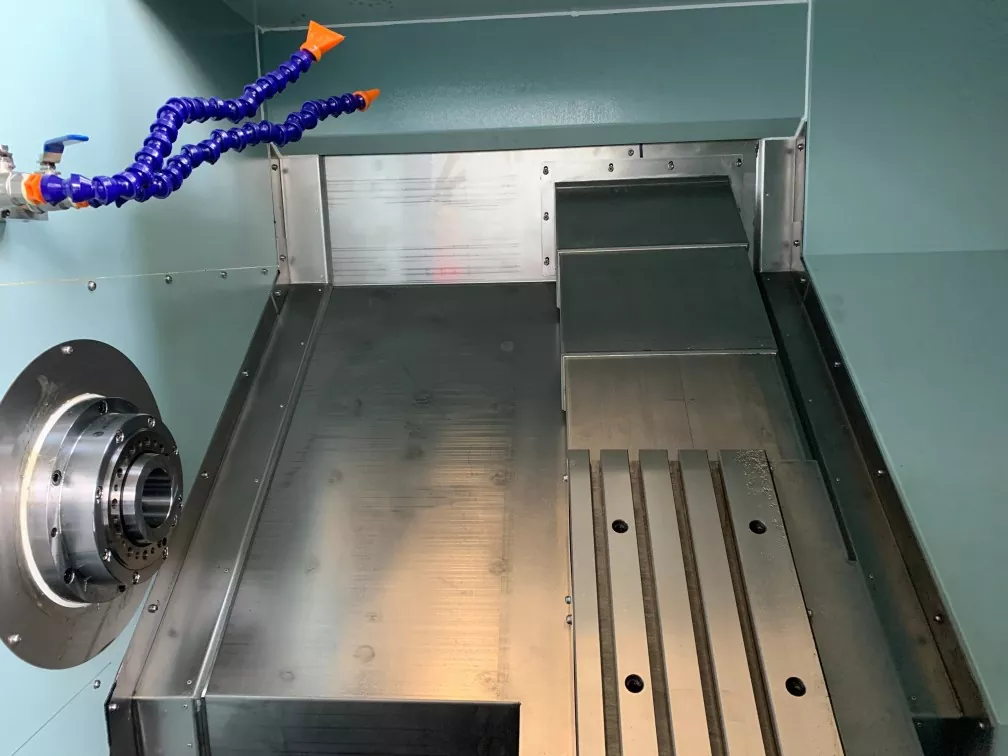

The 36-Row Tool CNC Machine Tools adopt a 45 degree overall inclined bed design, with the inclined surface sliding down to the chip removal groove, making chip removal more efficient in the later stage and reducing the risk of iron chips entangling the tool and working. Our bed is made of HT300 gray cast iron as a whole, and after processing, it is annealed to relieve stress. The bearing seat is integrated with the bed to improve the stability, rigidity, and machining accuracy of the machine tool.

The T-shaped cutting plate reduces tool changing time and improves production efficiency, making it versatile.35 degree inclined bed design, convenient for operators to clamp workpieces up and down, and smooth chip removal.The ultra large X-axis has a stroke of 800 and the Z-axis has a stroke of 300, making it convenient for cutting and installing power heads.

Product Parameter (Specification)

|

Processing capacity |

36A |

|

Spin the bed body |

φ400 |

|

The largest diameter processing |

φ300 |

|

Spindle |

|

|

Spindle nose |

A2-4 |

|

Bar aperture |

Φ36 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.003 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

24m/min |

|

Axial Stroke |

|

|

X-axis Stroke |

800mm |

|

Z-axis Stroke |

260mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

5.5KW |

|

X axis(servo)and motor |

1.3KW |

|

Z axis(servo)and motor |

1.3KW |

|

Other |

|

|

Weight |

2500KG |

|

Mechanical dimensions |

2135*1470*1713mm |

Product Festure And Application

High precision machining: such as precision molds, new energy industry, medical equipment parts processing, automotive parts, home appliance parts, etc.

Paired with a 2.5m fully automatic feeder, it saves labor costs and greatly improves production efficiency

Production Details

Single layer 2mm stainless steel full protection

The bed and bearing seat are integrally formed