- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

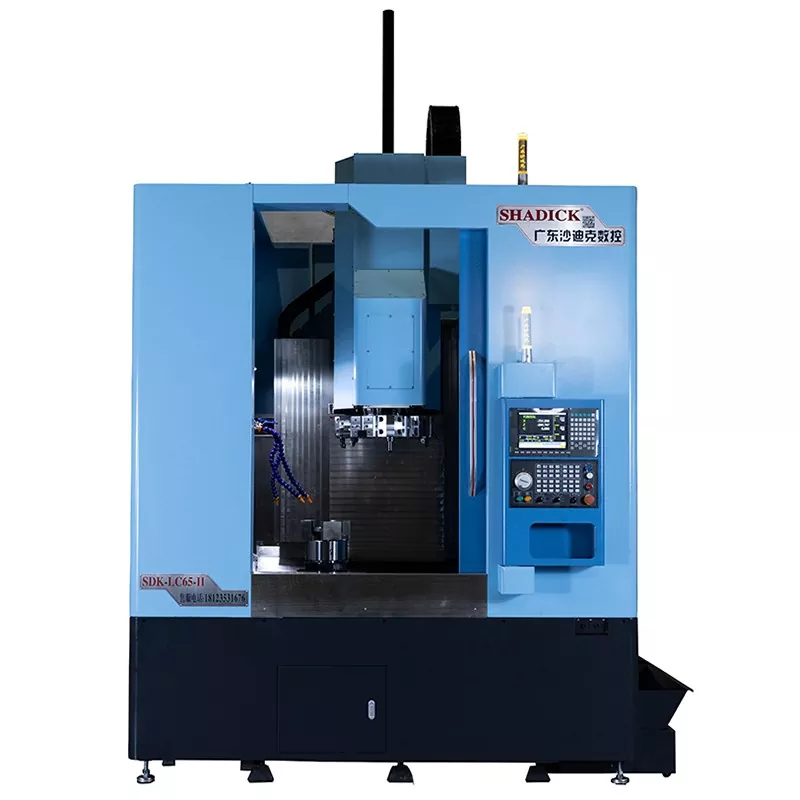

China Large-Scale Vertical CNC Machine Tools Manufacturer, Supplier, Factory

Shadick has accumulated profound experience over the years in the research, development, and manufacturing of Large-Scale Vertical CNC Machine Tools. For many years, it has continuously invested substantial resources in technological research, development, and innovation, delving deep into the core technologies of Large-Scale Vertical CNC Machine Tools. From the basic structural design of the machine tools to the manufacturing processes of key components, Shadick has formed a unique technical system.

Shadick's Large-Scale Vertical CNC Machine Tools adopt a unique high-rigidity structural design. Key components such as the machine bed and column are all made of high-quality, high-strength materials and manufactured through advanced casting or welding processes. This high-rigidity structural design enables the machine tools to effectively reduce vibrations and deformations during high-speed and heavy cutting processes, thereby improving machining accuracy and surface quality and extending the service life of cutting tools.

As a source manufacturer, Shadick provides customers with comprehensive technical support. Before customers purchase machine tools, Shadick offers professional model selection advice and machining plan formulation according to customers' machining requirements and technological requirements. During the installation and commissioning of the machine tools, technicians will provide on-site guidance for equipment installation and commissioning to ensure that the machine tools can be put into use smoothly. Additionally, detailed training will be provided to customers' operators, enabling them to master the operation methods and maintenance key points of the machine tools proficiently.

- View as

80 Vertical CNC Machine Tools

The 80 Vertical CNC Machine Tools is equipped with multi axis control, which flexibly adapts to the multi-faceted machining needs of complex workpieces. The workbench position is intuitive, the programming is simple, and it is convenient for operators to perform machining operations and program adjustments. It can handle a variety of materials, including metals, non metals, etc., to meet the processing needs of different industries.

Read MoreSend Inquiry60 Vertical CNC Machine Tools

The vertical layout of 60 Vertical CNC Machine Tools brings many advantages: its compact structure, small footprint, and suitability for work environments with limited space. The workpiece is naturally positioned by gravity during the machining process, which provides an extremely stable machining environment for cutting operations and ensures the achievement of high-precision machining.

Read MoreSend Inquiry