- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

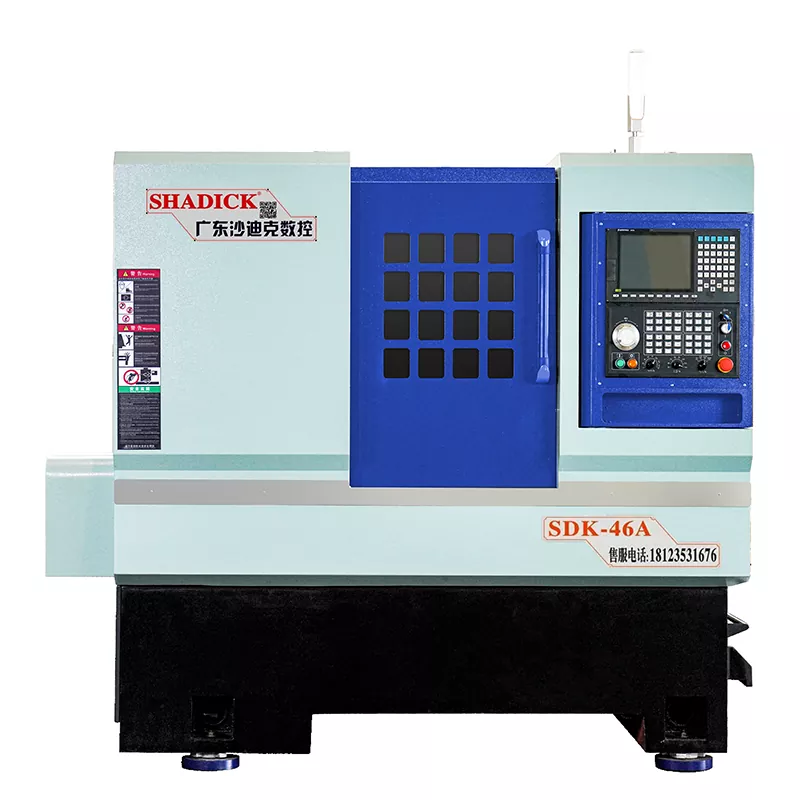

Power Head and Row Tool CNC Machine Tools

In the actual production process, enterprises often need to adjust their production processes according to market demand and production plans. After installing the power head, the Power Head and Row Tool CNC Machine Tools can easily cope with these changes, quickly adjust the processing plan and process combination to meet different production needs. This flexibility helps companies better adapt to market changes and enhance market competitiveness.

Send Inquiry

When installing a power head on a cutting machine, customers can choose from one to one, one to two, or one to three power heads according to their needs. Each configuration has its unique advantages: one to one power head works independently and is easy to maintain, one to two power heads can further improve production efficiency, and one to three power heads are highly automated, reducing manual labor and flexibly responding to diverse and complex processing needs.

Product Parameter (Specification)

|

Processing capacity |

46A |

52A |

|

Spin the bed body |

φ500 |

|

|

The largest diameter processing |

φ350 |

φ400 |

|

Spindle |

||

|

Spindle nose |

A2-5 |

A2-6 |

|

Bar aperture |

φ46 |

φ52 |

|

Spindle speed |

0-5000 |

0-3000 |

|

Mechanical precision |

||

|

Repeat positioning accuracy |

±0.005 |

|

|

Spindle firing |

≤0.005/100mm |

|

|

Spindle taper |

≤0.005/100mm |

|

|

X, Z crosshair |

≤0.005/100mm |

|

|

X/Z axis fast-moving speed |

24m/min |

|

|

Axial Stroke |

||

|

X-axis Stroke |

900mm |

|

|

Z-axis Stroke |

400mm |

355mm |

|

Motor Power |

||

|

Spindle(servo)and motor |

7.5KW |

11KW |

|

X axis(servo)and motor |

1.3KW |

1.8KW/2.4KW |

|

Z axis(servo)and motor |

1.3KW |

1.8KW/2.4KW |

|

Other |

||

|

Weight |

3200KG |

3300KG |

|

Mechanical dimensions |

2230*1600*1900 |

|

Product Festure And Application

In scenarios that require large-scale production or rapid completion of a large number of processing tasks, installing a one to two or one to three power head on the cutting machine can significantly improve production efficiency. By processing multiple workpieces simultaneously, waiting time can be reduced, and the processing flow can be optimized to achieve efficient production. In some processing workshops with limited space, installing compact power heads (such as small and lightweight power heads) on the Power Head and Row Tool CNC Machine Tools can fully utilize the limited space and improve space utilization efficiency. This configuration helps to achieve efficient processing and production within a limited space.

Production Details

Power Head and Row Tool CNC Machine Tools Internal structure of machine tool