- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

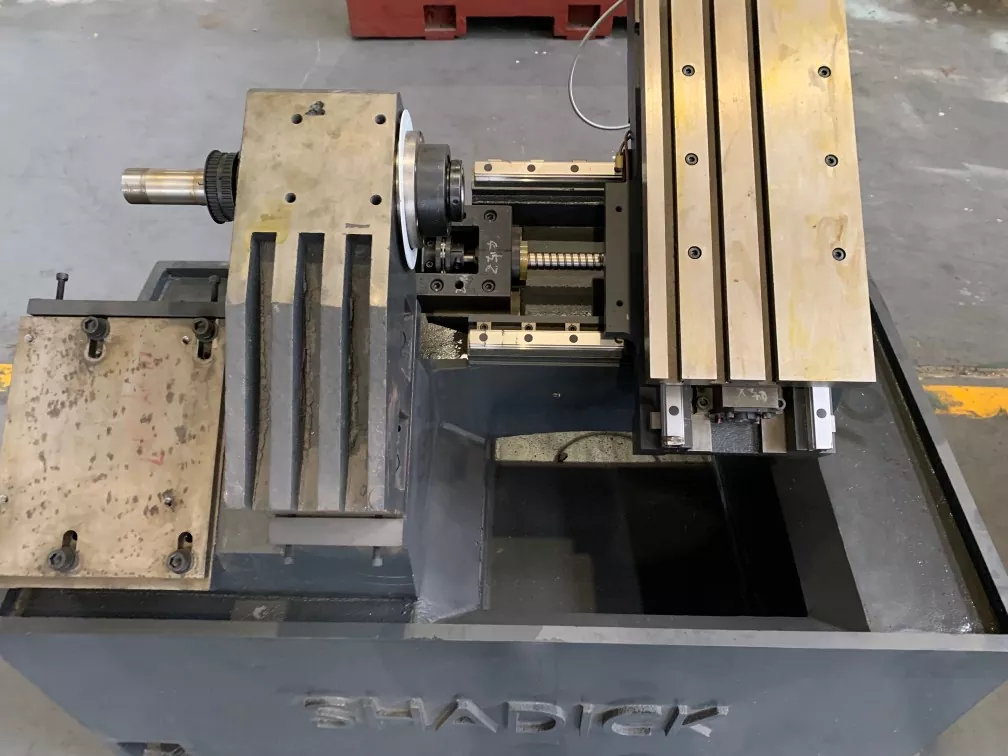

20-Row Tool CNC Machine Tools

20-Row Tool CNC Machine Tools have a small footprint and compact structure, making the tools very suitable for machining environments with limited space. At the same time, it is easy to operate and master, reducing the skill requirements for operators. In addition, the 20 machine also has the characteristic of high cost-effectiveness, making it an ideal processing equipment choice for small and medium-sized enterprises and startups.

Send Inquiry

20-Row Tool CNC Machine Tools adopt advanced pneumatic fixture system, designed specifically for high-precision spare parts processing. This model is equipped with full protective devices to ensure the safety and stability of the operation process. The casting is made of high-quality 300 grade cast iron, which has excellent rigidity and wear resistance, ensuring machining accuracy and workpiece quality.

Product Parameter (Specification)

|

Processing capacity |

20A |

|

Spin the bed body |

φ100 |

|

The largest diameter processing |

φ20 |

|

Spindle |

|

|

Spindle nose |

A2-4 |

|

Bar aperture |

φ20 |

|

Spindle speed |

0-6000 |

|

Mechanical precision |

|

|

Repeat positioning accuracy |

±0.005 |

|

Spindle firing |

≤0.005/100mm |

|

Spindle taper |

≤0.005/100mm |

|

X, Z crosshair |

≤0.005/100mm |

|

X/Z axis fast-moving speed |

22m/min |

|

Axial Stroke |

|

|

X-axis Stroke |

580mm |

|

Z-axis Stroke |

240mm |

|

Motor Power |

|

|

Spindle(servo)and motor |

3.7KW |

|

X axis(servo)and motor |

1.1KW/850W |

|

Z axis(servo)and motor |

1.1KW/850W |

|

Other |

|

|

Weight |

1200KG |

|

Mechanical dimensions |

1200*900*1500mm |

Product Festure And Application

20-Row Tool CNC Machine Tools are highly suitable for machining small precision parts, such as electronic components, micro mechanical parts, etc., due to its high precision and stability. This model is capable of handling the processing challenges of high hardness materials such as stainless steel, titanium alloys, etc., ensuring processing quality and efficiency.

Production Details