- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

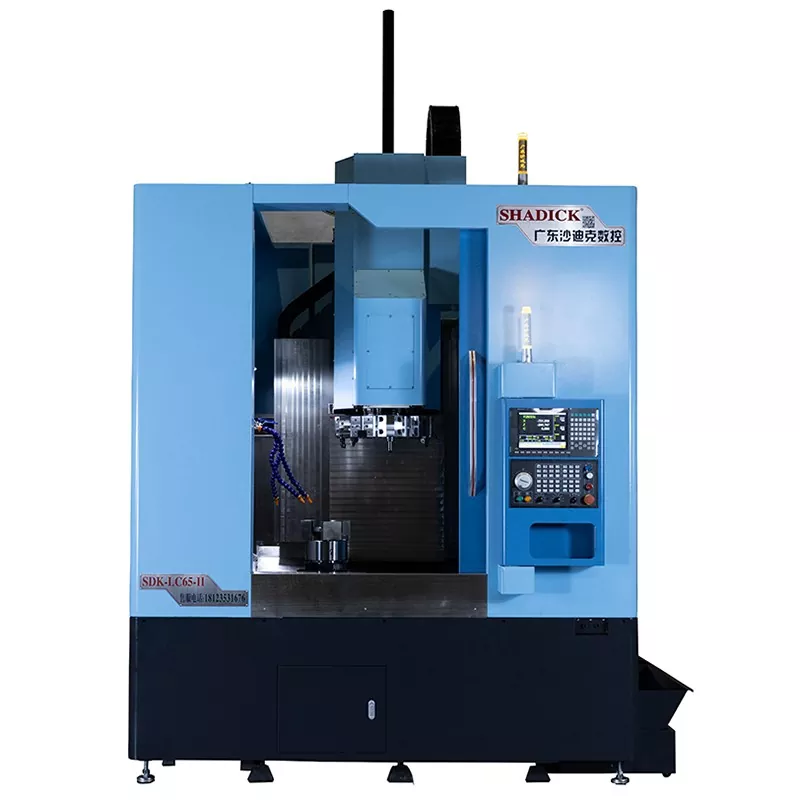

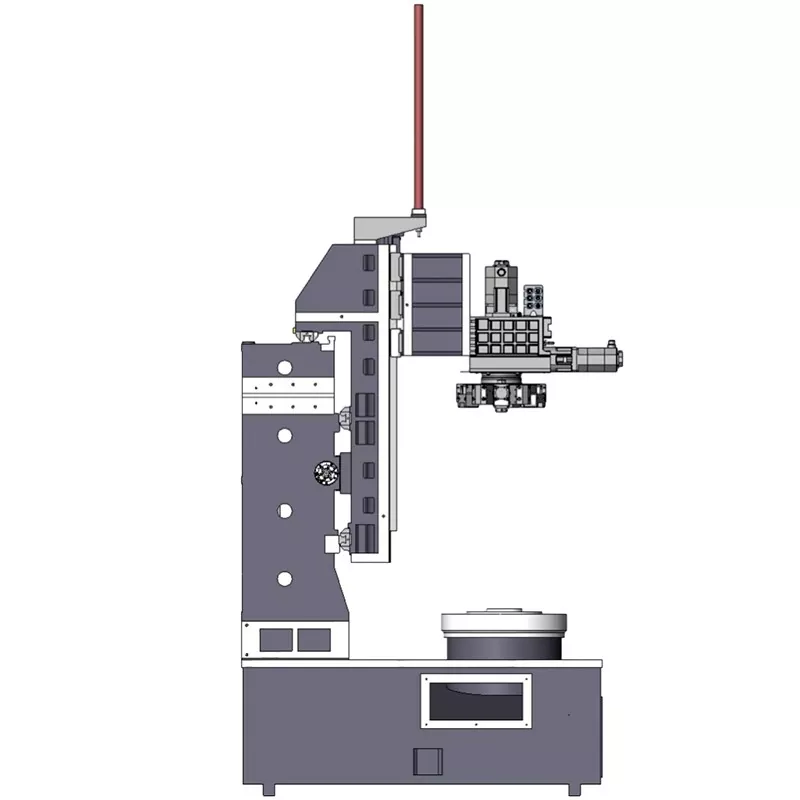

60 Vertical CNC Machine Tools

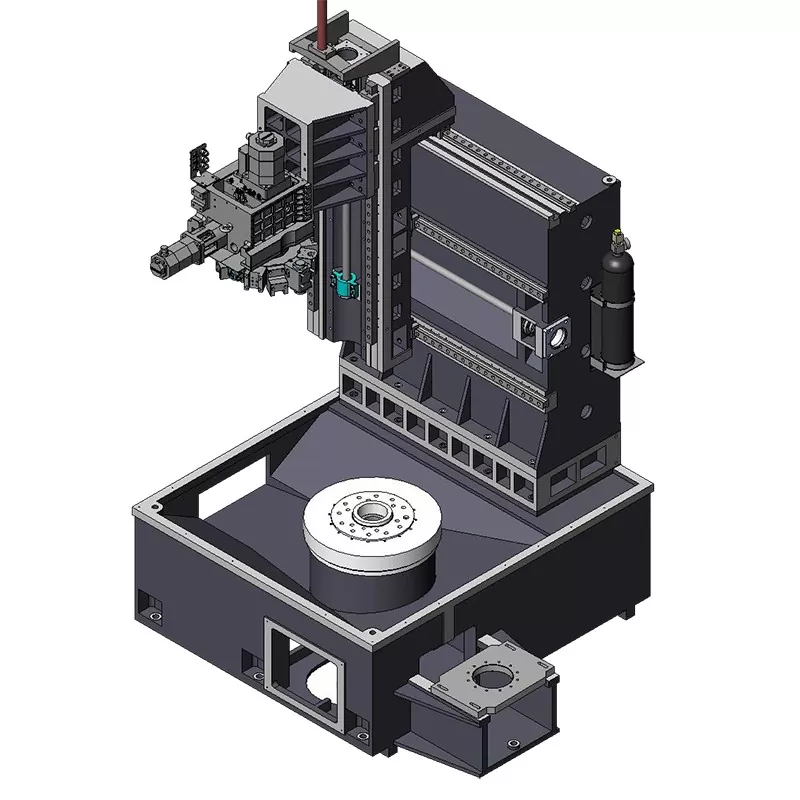

The vertical layout of 60 Vertical CNC Machine Tools brings many advantages: its compact structure, small footprint, and suitability for work environments with limited space. The workpiece is naturally positioned by gravity during the machining process, which provides an extremely stable machining environment for cutting operations and ensures the achievement of high-precision machining.

Send Inquiry

60 Vertical CNC Machine Tools are usually equipped with various accessories and tools, which can complete various machining tasks such as turning, milling, drilling, tapping, etc. They have strong adaptability and high flexibility, meeting diverse machining needs. The structural design of vertical machine tools facilitates integration with automated equipment such as loading and unloading devices and robots, forming automated production lines that achieve efficient and continuous processing operations, reduce labor costs, and improve production efficiency.

Product Parameter (Specification)

|

Processing capacity |

LC60 |

LC80 |

|

Spin the bed body |

φ700 |

φ850 |

|

The largest diameter processing |

φ600 |

φ800 |

|

Spindle |

||

|

Spindle nose |

A2-8 |

A2-11 |

|

Bar aperture |

φ86 |

φ60 |

|

Spindle speed |

0-2000 |

|

|

Mechanical precision |

||

|

Repeat positioning accuracy |

±0.008 |

|

|

Spindle firing |

≤0.008/100mm |

|

|

Spindle taper |

≤0.008/100mm |

|

|

X, Z crosshair |

≤0.008/100mm |

|

|

X/Z axis fast-moving speed |

24m/min |

|

|

Axial Stroke |

||

|

X-axis Stroke |

500mm |

|

|

Z-axis Stroke |

750mm |

|

|

Motor Power |

||

|

Spindle(servo)and motor |

15KW |

|

|

X axis(servo)and motor |

2.9KW |

|

|

Z axis(servo)and motor |

2.9KW |

|

|

Turret |

||

|

Turret |

8 workstations with 380 tool trays |

|

|

Other |

||

|

Weight |

9000KG |

11000KG |

|

Mechanical dimensions |

2450*2330*2650 |

|

Product Festure And Application

60 Vertical CNC Machine Tools are used in the automotive industry to process engine components, transmission housings, and other complex body structural parts. These parts usually require high precision and good surface quality, and vertical machine tools can meet these strict production requirements. Vertical machine tools, especially vertical lathes, are commonly used for processing large disc parts such as flywheels, flanges, brake drums, etc. These parts have larger radial dimensions, and the layout of the vertical machine tool allows it to easily meet the machining needs of such workpieces.

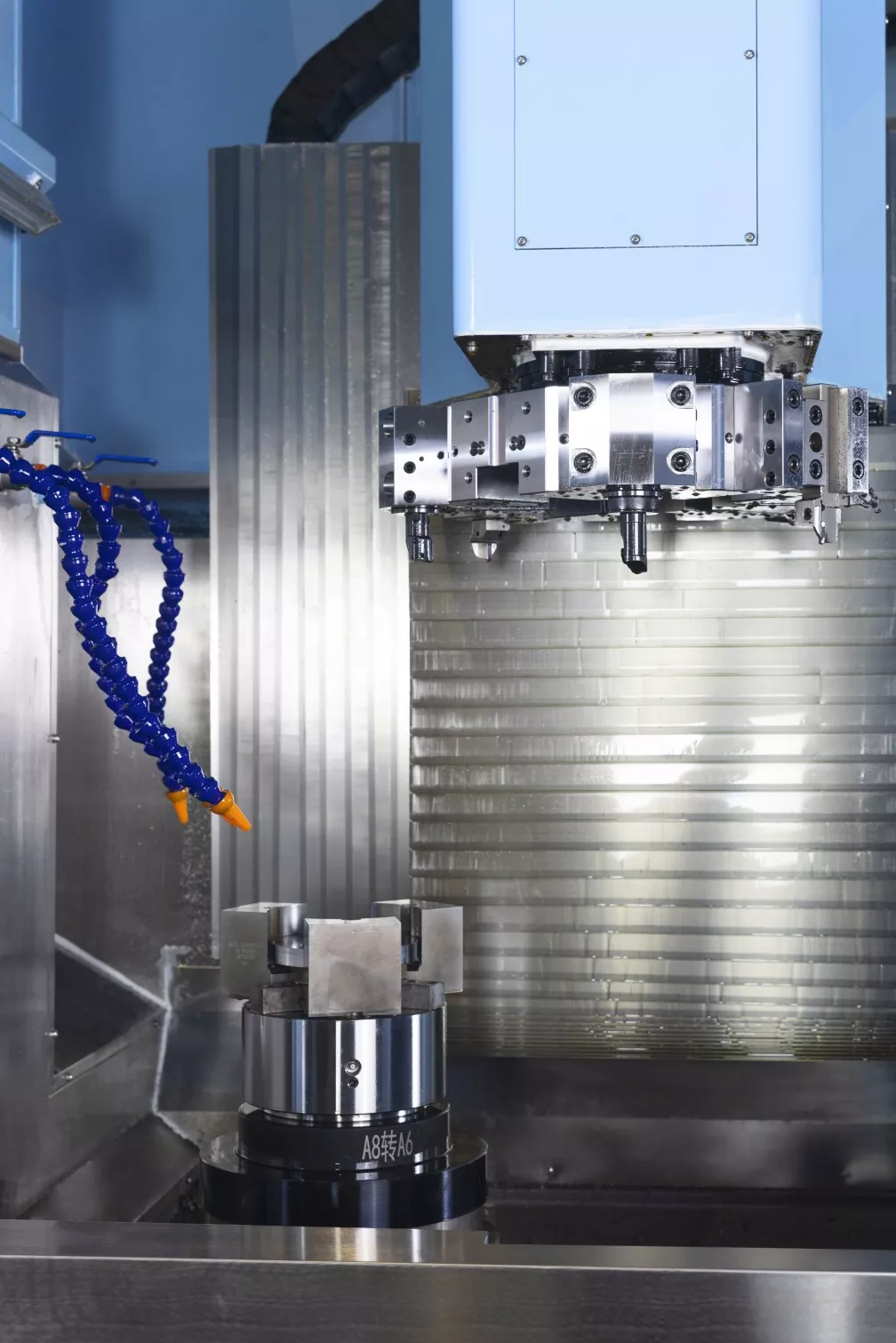

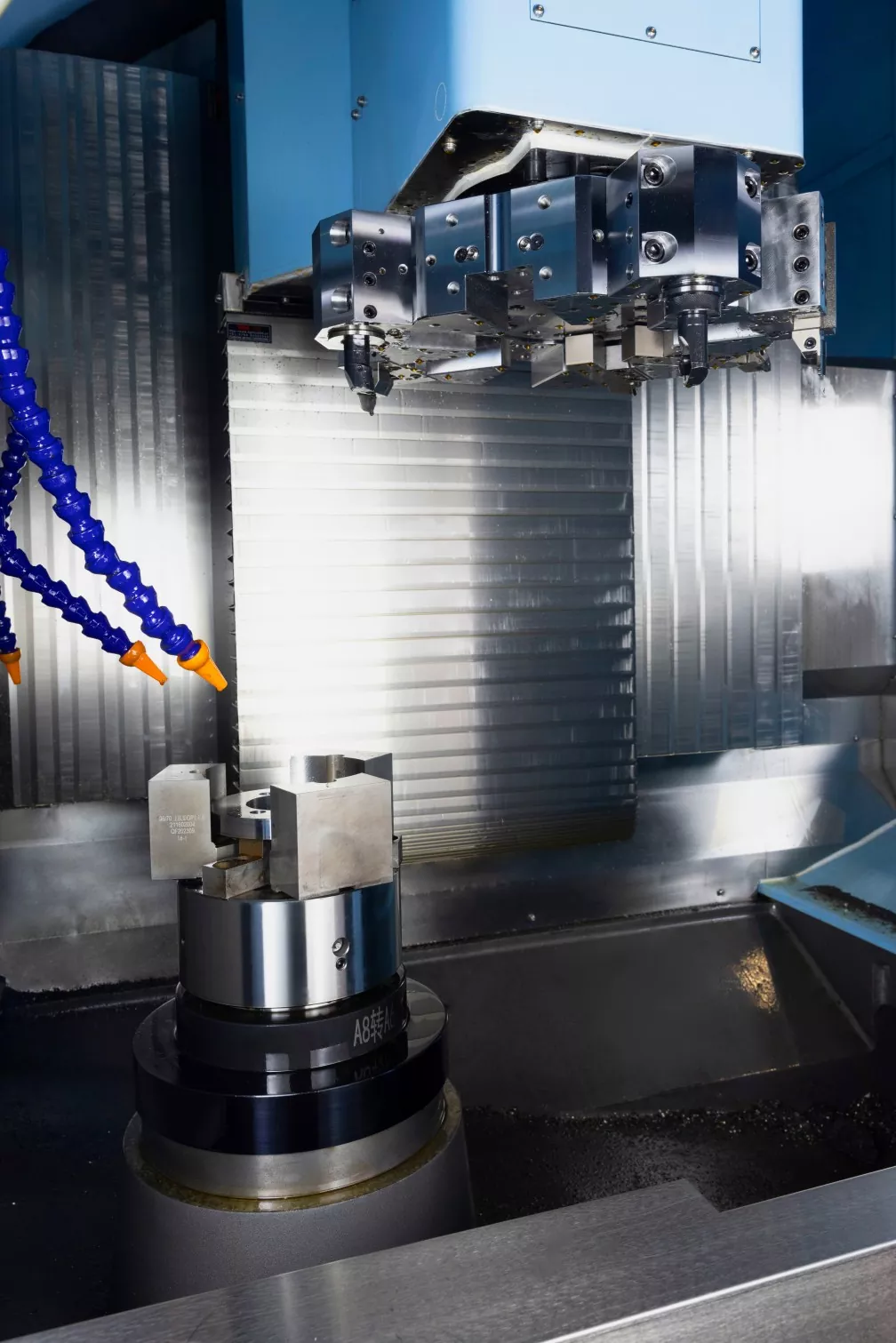

Production Details

Display of internal structure of machine tool