- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

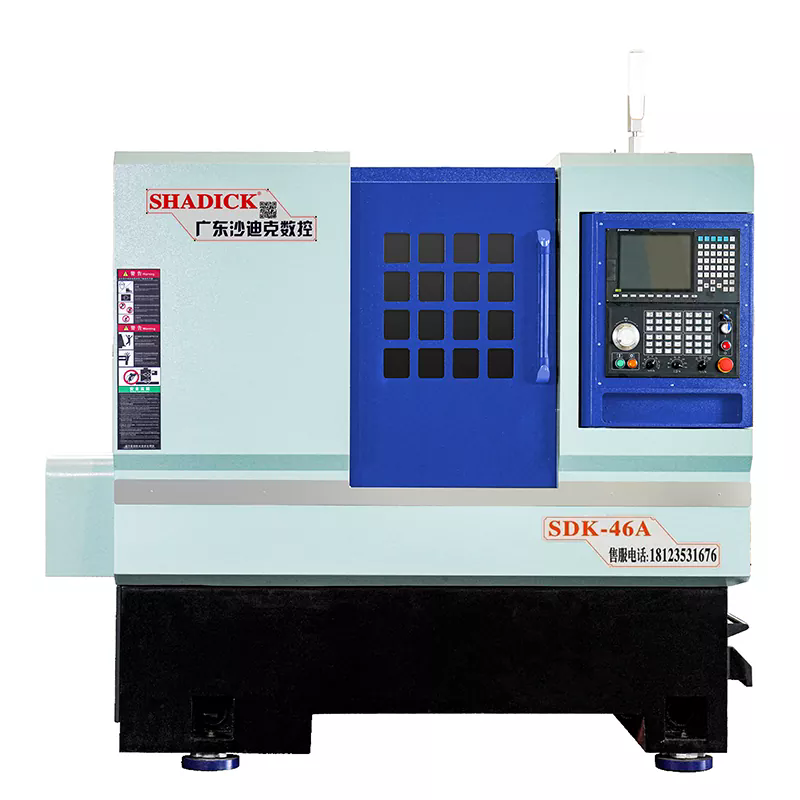

Why Are Row Tool Hobbing CNC Machine Tools Gaining Attention in Gear Processing?

Row Tool Hobbing CNC Machine Tools are high-efficiency equipment specially designed for gear manufacturing. With their high precision, efficiency, and flexibility, they are widely used in industries such as automotive, machinery manufacturing, and aerospace. By utilizing multiple rows of cutting tools working simultaneously, they significantly improve production efficiency and meet modern industrial demands for high-quality gears.

What Are the Significant Advantages of Row Tool Hobbing CNC Machine Tools?

These machines feature multi-tool simultaneous cutting, fast tool changing, and stable processing performance. The multi-row tool design enables continuous and efficient machining, greatly shortening production cycles. At the same time, the precise control of the CNC system ensures the accuracy and consistency of gear processing, meeting complex tooth profiles and strict tolerance requirements.

Why Are Row Tool Hobbing CNC Machine Tools Suitable for Small to Medium Batch Production?

With a compact structure and flexible operation, Row Tool Hobbing CNC Machine Tools are ideal for small to medium batch and multi-variety gear manufacturing. Their efficient tool change system and flexible machining solutions help enterprises quickly respond to market demands, balancing efficient production with cost control.

How to Choose the Right Row Tool Hobbing CNC Machine Tool?

When selecting this equipment, factors such as gear size, precision requirements, batch volume, and budget should be comprehensively considered. Different brands and models vary in performance, functionality, and after-sales service. It is recommended to choose suppliers with rich experience and a good reputation to ensure equipment stability and machining quality.

Why Is a Quality Supplier Crucial for Equipment Use?

A quality supplier not only provides high-performance Row Tool Hobbing CNC Machine Tools but also offers professional technical support, training, and after-sales services. This helps users solve various production issues, ensures long-term stable operation of the equipment, and improves production efficiency and product competitiveness.

For more information, please visit our website: www.shadick-cnc.com.