- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

What Are the Unique Advantages of Non-Standard Gang-Tool CNC Machine Tools?

2025-07-18

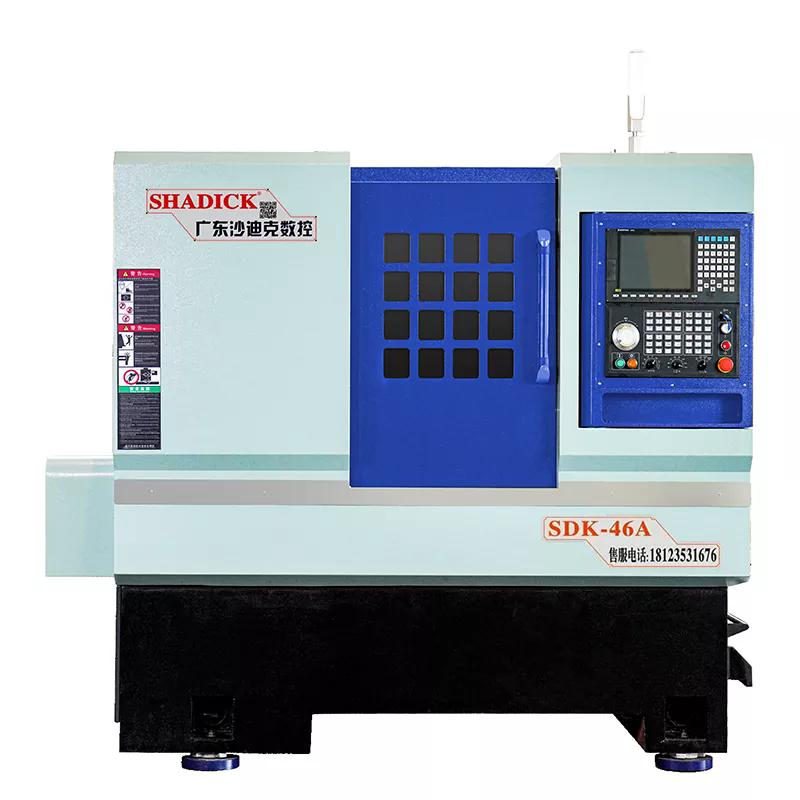

Non-standard gang-tool CNC machine tools are high-end equipment specially customized for unique gear machining needs. They break through the limitations of traditional standard machines to meet the high-precision and high-efficiency processing requirements of complex workpieces. Combining advanced CNC technology with personalized design solutions, they greatly improve machining flexibility and product quality. Widely used in automotive, aerospace, and machinery manufacturing industries, they have become crucial tools for enhancing production competitiveness.

How Do Non-Standard CNC Machine Tools Differ from Standard Machines?

Non-standard machines are designed based on specific customer needs, optimized for special gear shapes, sizes, and precision. Compared to standard machines, they focus more on process customization and multifunctionality, capable of handling complex angles, multi-axis linkage, and difficult-to-machine materials, significantly improving machining efficiency and yield.

What Benefits Can Enterprises Gain by Choosing Non-Standard CNC Machines?

Customized machines ensure machining accuracy while shortening production cycles and reducing manual intervention, enhancing automation levels. By adopting non-standard equipment, enterprises can achieve diversified batch production, lower manufacturing costs, increase market responsiveness, and gain more orders and customer trust.

Is Maintenance and Operation of Non-Standard Gang-Tool CNC Machines Complex?

Although the equipment has a complex structure, professional design ensures easy operation and convenient maintenance. Equipped with intelligent control systems and remote diagnostics, faults can be quickly identified and resolved, greatly reducing downtime and improving equipment stability and lifespan.

How to Find a Reliable Supplier for Non-Standard Gang-Tool CNC Machine Tools?

Choosing an experienced and technologically advanced supplier is critical. We specialize in R&D and manufacturing of non-standard gang-tool CNC machine tools, providing comprehensive customized solutions and professional after-sales service to support efficient production. For expert non-standard gang-tool CNC machine tools, precision gear machining equipment, and tailored CNC solutions, visit our website to learn more: [www.shadick-cnc.com].